Not many things in maintenance are predictable. One of them is equipment maintenance records. You know the drill: work is done, a record is updated. It’s a routine you can count on.

This article is about how to use that predictability to your advantage by taking the information you’re collecting anyway and turning it into the asset data you’ve been looking for. .

What is the importance of a maintenance record?

Having records that track maintenance activities is important for several reasons. Proper maintenance and keeping track of machinery maintenance records help you perform preventative maintenance to ensure that your equipment is in good condition, does not experience unplanned repairs, and runs as efficiently as possible throughout its useful life.

A maintenance log is also useful as a reference when deciding whether to replace your assets with updated versions and the best time to replace them. Data recorded over time reveals patterns of failures, expenses, and repairs. This can be used to make better decisions that will save costs and time.

How to create a great equipment maintenance record?

Obtaining accurate and reliable data from a maintenance record Equipment maintenance starts with how you build it. How you structure your maintenance records will depend on a variety of factors that are specific to your equipment and facility, but any record should consider three key questions:

- What asset and maintenance What information do you need more of?

- How detailed should the information be?

- Who is going to use this information and how?

This is typically divided into two sections: asset information and maintenance job information.

Best practice is to start with asset information at the top. This may include:

- Computer name (see this article for tips on setting up naming conventions)

- Serial number

- Location within of your facilities

- Manufacturer data (name, part number, contact information, date of manufacture)

- Date of purchase

- Date of service

Then describe the work that was done on the equipment:

- Date of the maintenance task

- Brief description of the task

- Name of person who performed the work

- Date of next scheduled maintenance

- Additional observations, notes, or comments

The simplicity is your best friend here. Don’t make it difficult for technicians to complete registration.

“It’s best to keep your descriptions short and all the key details clearly laid out,” says Jason Afara, Fiix Solutions Engineer.

“My rule of thumb is to put the same amount of effort into your logs as you would if you were trying to fix an asset and reading the log for the first time.”

Above all, make sure you have a process that ensures accuracy. There are three simple rules that will help you keep the data in your records as accurate as possible:

- Use a standard template for each asset. Equipment should be tracked and measured from the same baseline to avoid errors and make data analysis easier.

- Keep your records in a designated location. Bonus points for making them available on a digital platform for quick access and less risk of damaging or losing them.

- Create a routine for exchanging records between shift changes. Keep everyone informed about completed or pending work, issues, safety risks, and other helpful information.

How do you keep maintenance records?

Do you keep maintenance records? How you keep a maintenance log depends on whether you are doing it by hand or using maintenance logging software. If you are keeping maintenance records manually such as in a spreadsheet, here are three tips:

- Create a standardized template for each asset you want to track. Ideally, you want to try to keep these templates as consistent as possible to streamline your process.

- Designate a single place to keep records, so all maintenance workers can easily find them.

- Define the process for how equipment maintenance records should be exchanged and communicated between workers during shift changes.

If you are using software to create a maintenance schedule, workers Maintenance staff should know how the tool works and who to contact if they have questions. The best way to keep records, in this case, is to create a standard process for entering data to ensure it is entered consistently and in the same format.

Equipment Maintenance Record Template

The following template is similar to the one Jason used during his time leading a maintenance team.

“We wanted a record that would give us everything we needed to know to get a historical basis for our decision making, but was simple enough to fill out and read,” says Jason, “if you felt like as the effort of filling it out or reading it was not worth the result, it was not going to be used properly.”

Make your equipment log your own. Customize it as much as you want as long as it captures the most important information in a way that’s easy to interpret.

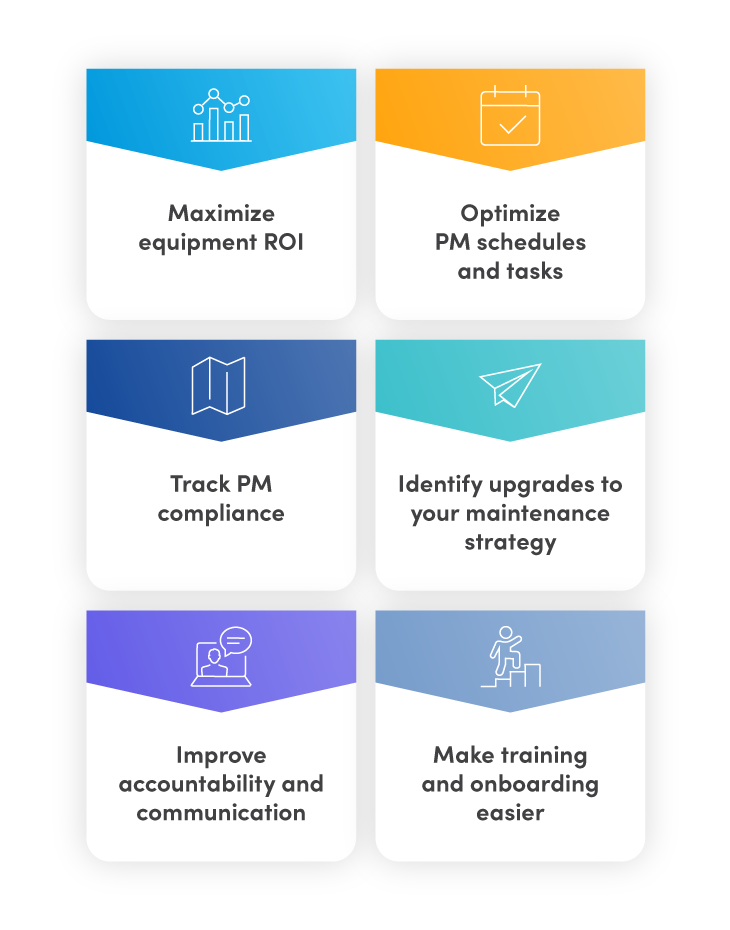

Six Ways to Use Data in Equipment Maintenance Records

Good- The Saved equipment maintenance records are great for looking back, but they can also help you create a better future for assets, maintenance equipment, and the organization as a whole.

#1 Maximize Equipment ROI

Equipment maintenance records allow you to compare equipment records from different vendors and see which one is more reliable. Choosing the most reliable supplier for future equipment purchases reduces the frequency of breakdowns, which means less maintenance costs and more production.

Records can also be the first indicator that equipment needs to be replaced soon. place to repair. It is possible to see if an asset breaks down more frequently and compare the cost of additional maintenance with the cost of a new asset.

A record is also proof that an asset has been properly maintained, increasing its resale value.

#2 Optimize Preventative Maintenance Tasks and Schedules

Well-kept records tell you if a piece of equipment is breaking down right after scheduled maintenance or before the next scheduled maintenance date. If this becomes a pattern, it’s time to rethink how you’re performing preventive maintenance on that asset and tweak it to prevent breakdowns. Equipment maintenance records also provide the information needed to make PMs quick, easy, and effective. For example, it tells technicians how previous issues were resolved or if changes were made and how they affected equipment.

#3 Track Preventive Maintenance Compliance

You can plan all the maintenance you want. you want, but an equipment maintenance log can tell you if the job is actually being done. Records clearly show when maintenance is scheduled and if any action was taken that day. There is no guessing or searching. The logs are an early warning system for poor preventive maintenance compliance. It’s easier to troubleshoot and avoid unplanned downtime when you can see red flags from a mile away.

Create a routine to swap records between shift changes. Keep everyone informed about completed or pending jobs, issues, security risks, and other useful information.

#4 Identify opportunities to update your maintenance strategy

You probably have a maintenance strategy for each piece of equipment. Maybe you decided after a lot of thought or maybe that’s how it’s always been done. In either case, equipment maintenance records can help you find opportunities to improve this strategy. For example, are you using preventative maintenance when run to failure could be just as effective with lower costs? Is the asset a good candidate for condition-based maintenance? Looking for patterns in equipment maintenance records is one way to answer those questions with data rather than hunches.

#5 Improving accountability and communication

Equipment maintenance records Teams reinforce accountability and communication, two of the most important elements in a successful maintenance program.

“Records are an additional form of communication and accountability for the maintenance team,” says Jason.

“They put people’s names next to work and allow necessary communication between staff working different shifts.”

#6 Facilitate training and onboarding

Detailed, well-organized maintenance records help new technicians get up to speed quickly. Working with unfamiliar machines usually means a lot of time shadowing an experienced worker and a bit of trial and error. This is not only unproductive, but can also lead to more errors and breakdowns. Equipment maintenance records provide new technicians with critical information about an asset, such as age, common problems, and where to go if they need more details. They can learn faster, make decisions with confidence, and stay safe in the process

Getting Data from an Equipment Maintenance Record

There is a lot of data in equipment maintenance records, but that does not mean that all that data is useful. The most valuable information is accurate, readily accessible, and presented in a way that is easy to understand.Using CMMS software is one way to check all of those boxes.

- A CMMS, especially a mobile CMMS, allows you to access equipment maintenance records on any Internet-connected device anywhere. Anytime, Anywhere

- The software automatically records and syncs data with other systems so information is always accurate and up-to-date

- The CMMS connects to the maintenance schedule, making it easy to tracking who did what and how efficient the work was

- Information from equipment maintenance records is searchable in a CMMS, which means you can filter work by asset, task, date , technical and more

- Data is stored securely in the cloud, so there’s no chance of it being lost or corrupted, unlike paper records

- You can attach images or videos to the maintenance record in a CMMS, which makes information clearer than just a written description

There is more to equipment maintenance records than meets the eye

Yes, equipment maintenance records can be boring and repetitive. But with a little shift in thinking, they can also be used to unlock key information and drive higher asset performance through data-driven maintenance. It all starts with a well-built template, solid processes, an understanding of what’s possible, and the tools to act on your plan. When all those ingredients come together, equipment maintenance records offer a way to use the past to create a better future for your facility and assets.

.